Gear Cutting & Grinding

Gear Cutting & Grinding

With our CNC precision machining expertise, we have utilized the opportunity to expand our business and create one of India’s first world-class facilities for the design and production of complex aerospace quality gears and gearboxes. The facility incorporates state-of-the-art, closed-loop gear cutting/grinding & quality equipment.

We aim to build niche capabilities through competency, capability, and necessary technical infrastructure in high-end precision gear manufacturing. We are committed to contributing to the global aerospace gear market in both the aero-engines and rotary platforms.

Machinery

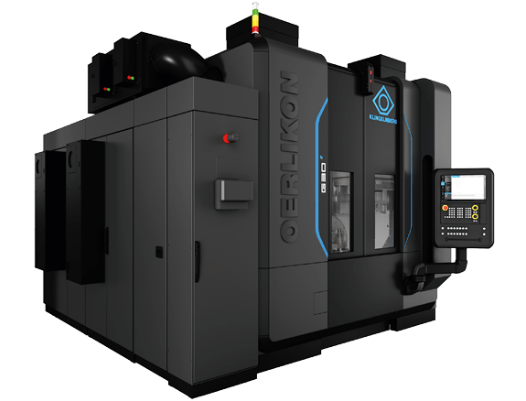

KLINGELNBERG OERLIKON G20 (SPIRAL BEVEL GEAR GRINDING)

MACHINE SPECIFICATION:

Workpiece diameter (max) = 200mm

Facewidth (max) = 60mm

Number of Teeth (max) =360

KLINGELNBERG HOFLER VIPER 500KW (CYLINDRICAL GEAR GRINDING)

MACHINE SPECIFICATION:

Workpiece diameter (max)= 500mm

Grinding stroke = 430mm

STUDER FAVORIT (ID/OD CYLINDRICAL GRINDING)

MACHINE SPECIFICATION:

Workpiece diameter (max) = 349mm

Workpiece length (max) = 400mm